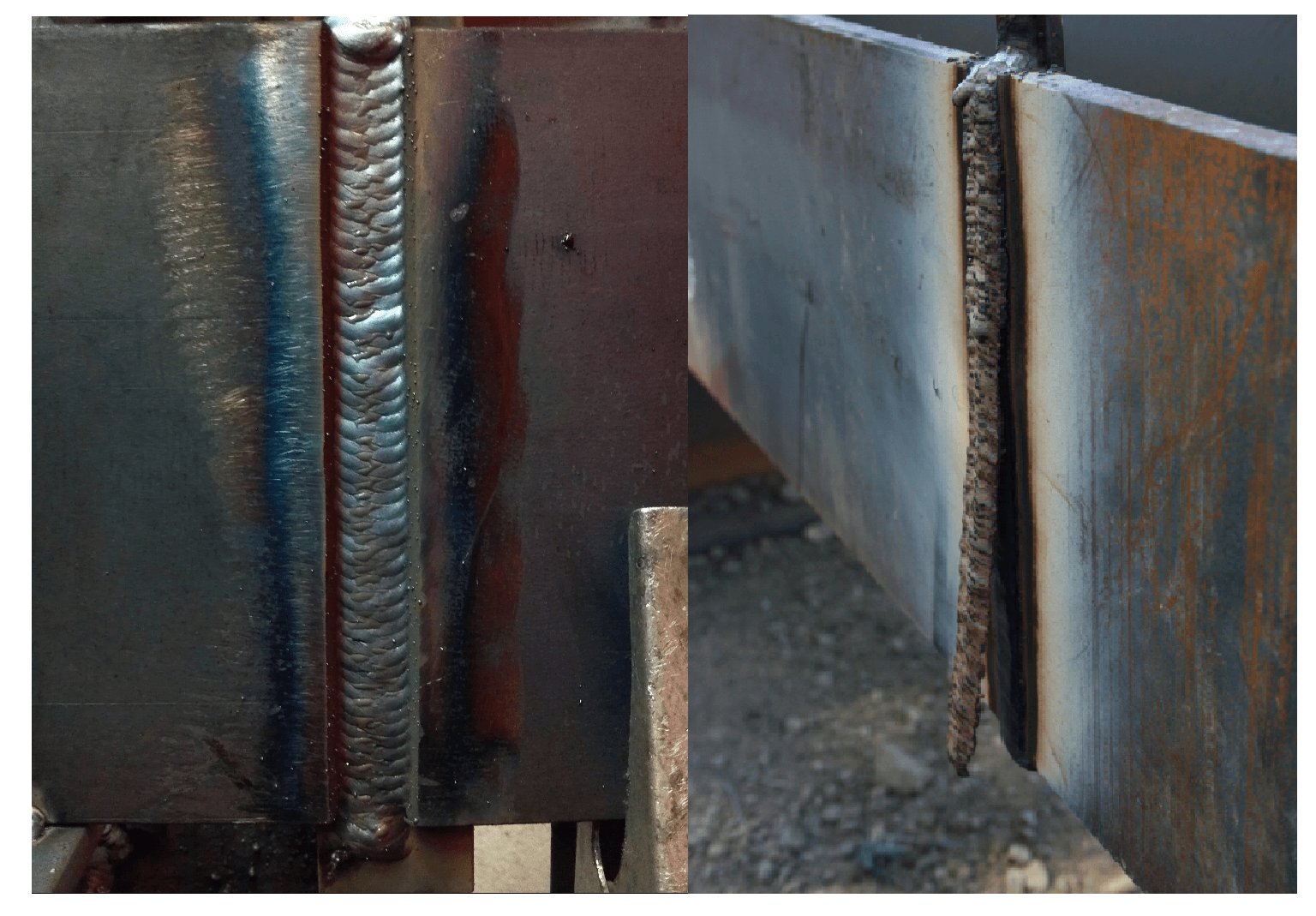

Vertical up fluxcore weave! 25.0v 275wire r/Welding

Getting to Know Fluxcore Wire

Matt Underwood, welding engineer/CWI at Hobart, explains how to set up equipment and select the proper welding parameters for welding with Fabshield XLR-8 self-shielded flux-cored wire, as well as demonstrating gun angles and techniques for welding vertical up.The Hobart® Fabshield® XLR-8™ increases productivity in flat/horizontal or out-of-position welding compared to AWS E7018 stick.

MIG Welding Gas vs Flux Core Beginner Welding Guide

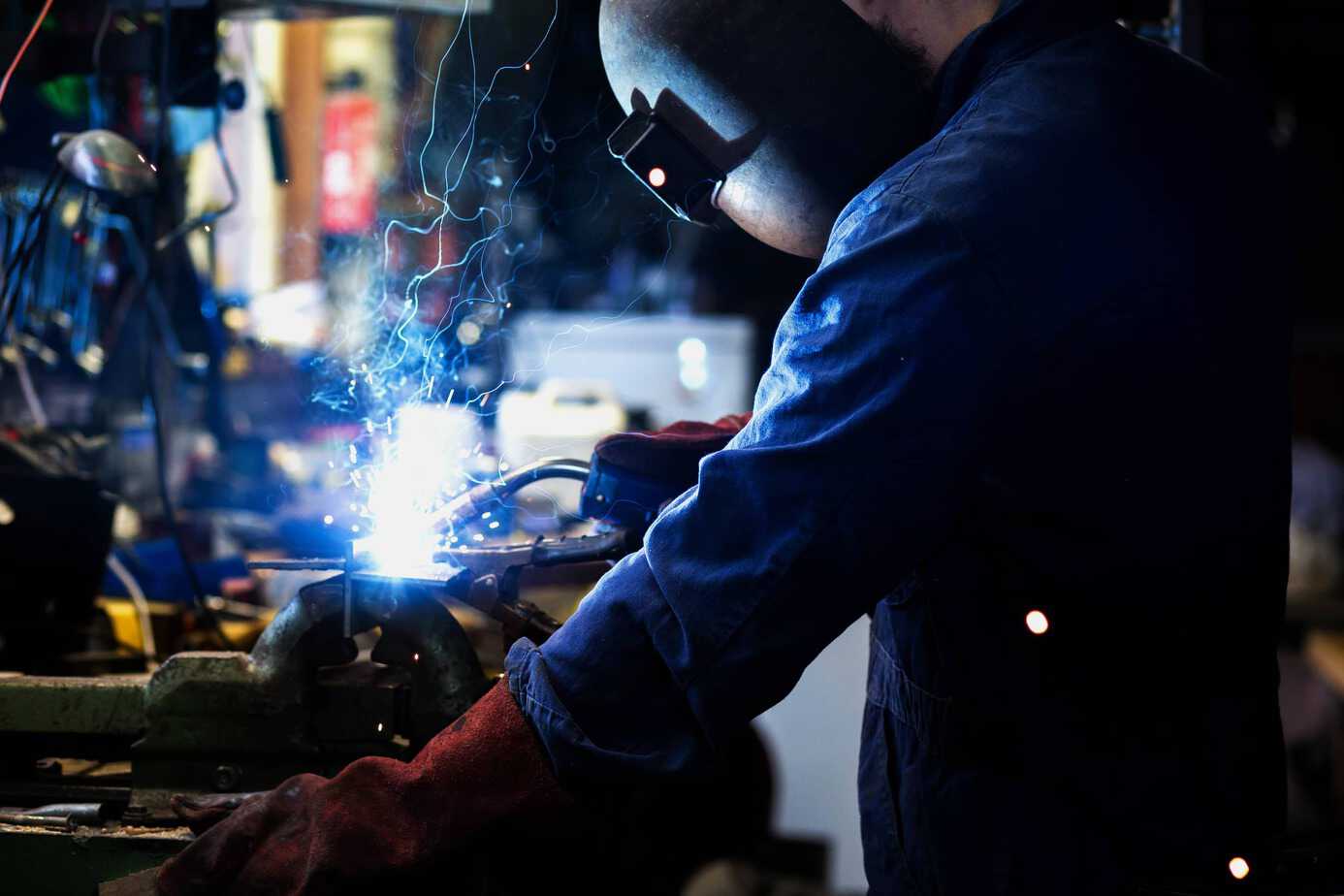

Years of practice resulted in the Flux core welding (FCAW) method, which is just like MIG welding but uses a self-shielded wire based on stick electrodes.. Vertical welds, both up and down, can be tricky since you are fighting with gravity. To get the best results, you will have to tune down the machine for 10-15% of the recommended settings

Flux Core Welding The Basics You Need to know YouTube

P assing the AWS Structural Welder Qualification Test (vertical up certification on Flux-Cored Arc Welding) can be problematic for some, but insuring the right procedures and techniques are used should make things a lot easier. The good thing about this qualification is that if passed it certifies the welder no just in the 3G position, but also in the 1G, 2G, 3G, 1F, 2F and 3F positions.

5 Tips for Flux Core Welding Beginners How to Weld with Flux Core YouTube

Keep in mind, for materials thinner than 3/16 in., vertical-down welding is the most common technique. If the part you're welding cannot be positioned safely so the welds are in the flat or horizontal position (1G/F or 2G/F), then 3G/F (vertical-up) may be the only option. For thick sections, the best performance comes from welding vertical.

Flux cored arc welding dopkm

#welder #welding #fluxcoreIn this video, Kase Ford, Welding Instructor at Tulsa Welding School, shows a fluxcore vertical weld.Tulsa Welding School was found.

How to weld with flux core? What Is Shielding Gas Used for Fluxes Cored Arc Welding? Flux

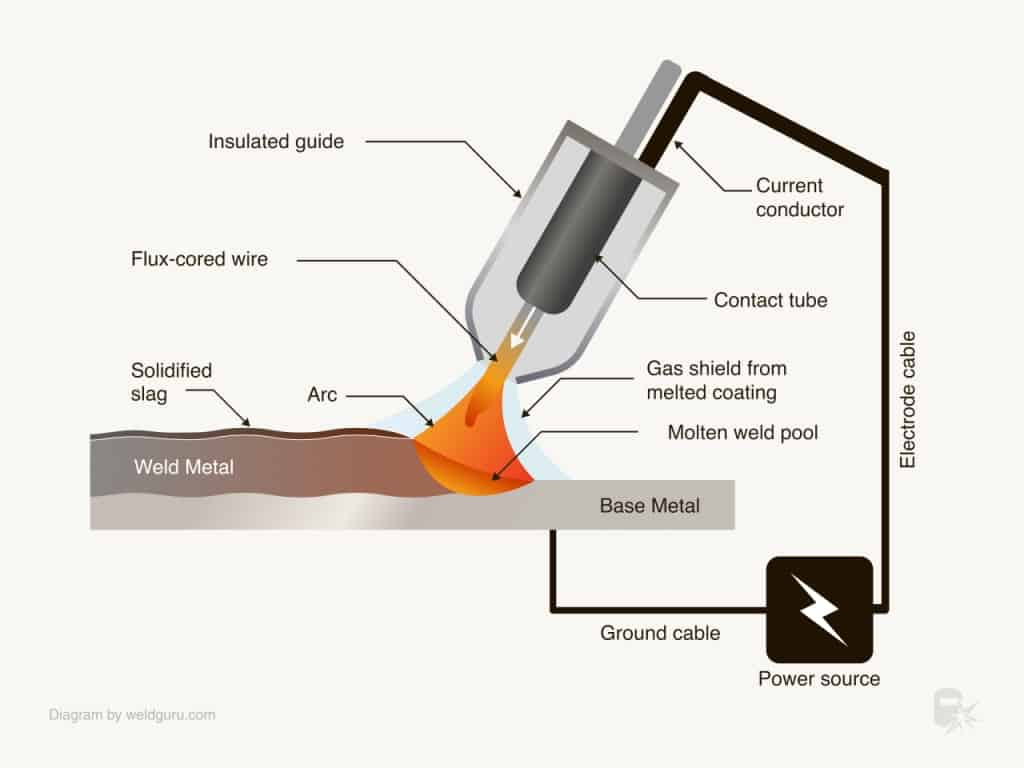

Flux-core arc welding (FCAW) is a popular arc welding process that uses a constant voltage power supply and a flux-filled tubular wire as filler material. The filler wire also acts as the electrode to start the arc and feeds into the weld puddle to form a weld bead. Flux-core welding can be manual, semi-automatic, or automatic, and many.

Advanced Gas Metal Arc Welding (GMAW) and Flux Cored Arc Welding (FCAW) Baker Technical Institute

Vertical up-flux core welding typically requires a voltage range of 22-29V, with a wire feed speed of 75-250 inches per minute. Amperage settings can vary from 90 to 280A depending on the wire size and material thickness. Vertical up flux core welding, frequently employed in the construction and shipbuilding industries, demands precise settings.

Flux core welding YouTube

2. For test assembly 4.2A the fillet weld lap joint and fillet weld T-joint are required. e. Test assemblies 4.1, 4.2A and 4.3B shall be welded in the vertical and overhead positions. f. Vertical weld test assemblies shall be both upward and downward progression. g. Test assembly 4.4 shall be performed with 18 gage ASTM A570 Gr.40 welded in the.

Dual Shield Flux Core E71T1 Vertical Up 3G. Showing the root pass, two stringers, and 3 cover

Vertical and flux-cored wires. With the proper flux-cored wire, you can weld vertically both up and down. If the number before the "T" in the wire's designation is 1 (Ex1T-x), you can weld vertically. But if it's 0 (Ex0T-x) you cannot. Flux-cored wires are tubular, filled with flux material that creates slag.

The Complete Guide to FluxCored Arc Welding Welding Headquarters

*Wire Feed Speed is a starting value only and can be fine-tuned while welding. **CO 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. 75% Argon / 25% CO 2 is better on thin steels, produces less spatter and better bead appearance.. Settings based on butt welds. Joint design, fitup, backup, position, bead size and stickout may alter conditions.

Flux Core Welding How To, What Is It, Tips Maritime Herald

FCAW Machine Set Up C25 Fluxed Core Dual Shielding Gas . Setting up of the flux cored welder was not hard. I used the same Millermatic 350P that I did my 3G vertical up MIG welding certification with. All I did was change the wire from MIG wire, to flux cored E71T-1 dual shielding wire, and then the rollers. The bottle of gas on the machine was.

What is Flux Core Welding? WeldingWatch

Generally, try to use a stickout of around ¾ of an inch. 6. Get a Good & Secure Ground Connection. The ground connection completes the circuit, allowing the welding process to work. A good and secure ground connection is critical, regardless of the type of welding that you do, and flux core welding is no exception.

VERTICAL Flux Core Groove Weld D1.1 Weld Test 3G Uphill YouTube

For a beginner, an ER70S-6 .030″ diameter wire will create a small enough puddle. This diameter is suitable for 120V MIG welders and welds uphill up to 1/4″ thick metals with solid results. A .035″ wire would be more practical for thicker metals, but you need a 240V welder to get the necessary amperage and duty cycle.

Vertical up fluxcore weave! 25.0v 275wire r/Welding

Once you have a base, the next step is to weld diagonally up into the joint. Your torch should move from the right-hand side up into the centre of the joint. Next, weld diagonally down to just above where the weld started. The entire motion looks like a triangle. That's the first triangle done.

Gasless Flux Core Welding Basics for Beginners WeightBlink

Today we're showing how to do a vertical flux core groove weld with a backer. In addition to the welding technique, we will go into detail on how to read the.

What is FluxCore Arc Welding (FCAW) & How Does it Work?

This is another long one fellas. Way too many of you guys are asking about this so instead of replying to each of you one at a time I'm just going to link th.